Authors

Drapper Environmental Consultants, Springfield Lakes, Queensland, Australia

Darren Drapper, Principal, Drapper Environmental Consultants

SPEL Environmental, Carole Park, Queensland, Australia

Andy Hornbuckle, Team Leader Asia Pacific – Water Quality

Read full article.

Abstract

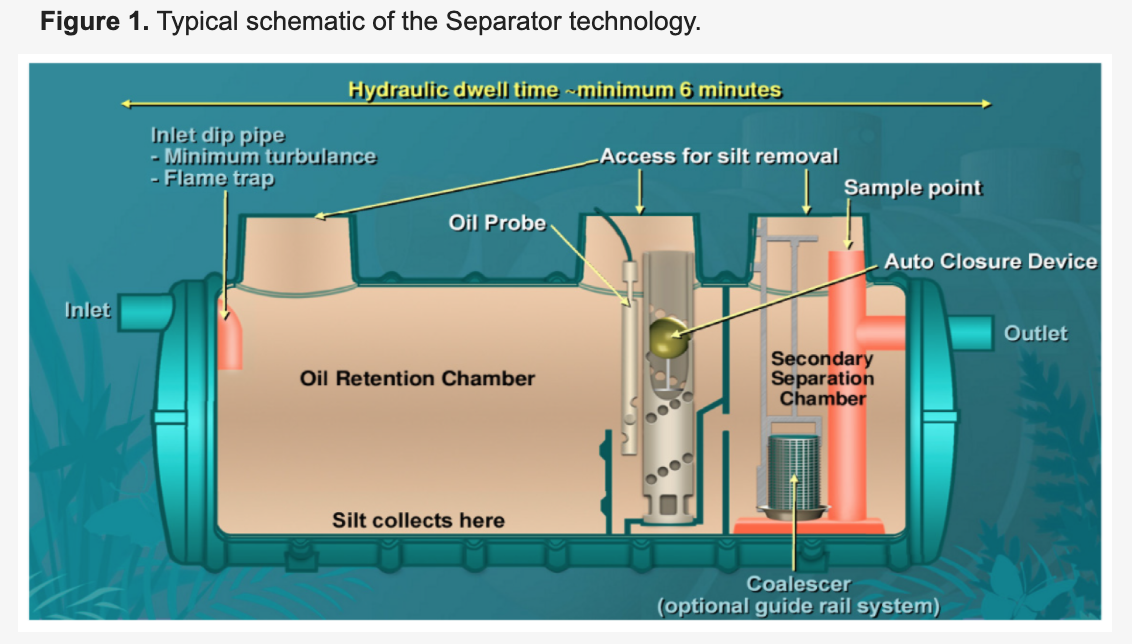

Hydrocarbon spills and management in the marine environment are of significant environmental and public health concern and the subject of many research projects. In freshwater environments, the treatment and management of hydrocarbons from point and diffuse sources appears less well investigated. For hydrocarbon treatment technologies introduced into the European market, they must be tested and comply with the requirements of the European Standard EN BS858-1-2002. This Standard requires laboratory testing of full-scale models. Testing of several models of a hydrocarbon capture technology was performed in accordance with EN BS858-1:2002 at the HR Wallingford, United Kingdom (UK) and repeated at the University of South Australia (UniSA) laboratories. The results of the laboratory testing demonstrated compliance with the Standard’s Class 1 criteria of less than 5 mg/L of hydrocarbons in the effluent. Field testing of several concentrations conforming to the Class 1 requirement of <5 mg/L hydrocarbons.

1. Introduction

Point-source hydrocarbon spills are a significant environmental concern worldwide, whether they are from deep sea drilling rigs such as the Deepwater Horizon, bulk transport shipping or local dumping [

1,

2,

3]. On a smaller scale, research from Johns Hopkins Bloomberg School of Public Health raises concerns that significant amounts of fuel spilt at petrol (gas) refilling stations can be carried away with stormwater runoff into drainage networks or groundwater causing environmental and public health concerns [

4,

5]. International research has confirmed the presence of hydrocarbons in stormwater runoff from urban surfaces, in conjunction with heavy metals, nutrients and sediment [

6,

7,

8,

9,

10]. With the higher risk of fuel leaks and spills associated with refueling stations, many environmental protection agencies have implemented procedures and policies for the capture, treatment and removal/disposal of potentially contaminated runoff [

11,

12].

Management measures vary from a blind sump to capture all runoff and spills for later removal by vacuum truck; to “soft” engineered systems such as bioretention areas; and engineered technologies relying on retention time and coalescing media [

7,

13]. A blind sump consists of an underground concrete tank that collects the drainage from the bunded and covered forecourt (refueling) area and the bunded refill-box where tankers unload to the underground fuel tanks. A bund is any raised area, embankment or wall typically surrounding an area to keep spills contained or external overland flows out. Some bunds are vertical walls, whilst others can be formed in the pavement to drive over. Any fuel spills and wind-driven rain that falls within these bunded areas is captured by the blind sump, and must be regularly emptied by vacuum truck. The disadvantage of the blind sump is that, once full of rainwater, if a spill occurs, the capture volume available is reduced and could possibly result in overflow to drainage networks and the environment. The blind sump also is susceptible to human error in that it relies on inspection of the water level and engagement of a vacuum truck to remove the oily water as soon as possible after the rain event.

The function of natural vegetation and microbial action for hydrocarbon control has been demonstrated in several marine environments [

14,

15]. Less information is available on the field performance of natural systems in fresh (stormwater) environments. Bench-scale laboratory testing of bioretention columns for hydrocarbon removal, at the University of Maryland, observed that a 3 cm mulch layer provided a removal efficiency of approximately 80% for simulated storms [

13]. They indicate that the mulch is an essential ingredient in effective hydrocarbon removal. The disadvantage of this approach is that without a mulch layer, it could potentially lead to soil contamination over time and possibly costly remediation.

A variety of proprietary technologies have been developed internationally for medium to high risk vehicle refueling sites such as service station forecourts and underground petroleum tank fill points. This paper presents results of several case studies testing hydrocarbon capture for a separator technology that utilizes hydrodynamic separation and coalescing media on Stormwater and compares against the requirements of the Class 1 criteria from BS EN858.1-2002 [

16]. Testing has been undertaken in both laboratory and field installations across a number of different sites and model sizes.

To know more and understand better, you may read the full article here.